Porosity in Welding: Identifying Common Issues and Implementing Ideal Practices for Avoidance

Porosity in welding is a prevalent issue that commonly goes unnoticed up until it causes substantial issues with the honesty of welds. In this discussion, we will certainly discover the essential variables contributing to porosity formation, analyze its harmful results on weld efficiency, and go over the best methods that can be taken on to reduce porosity occurrence in welding processes.

Common Root Causes Of Porosity

Another frequent offender behind porosity is the existence of pollutants externally of the base metal, such as oil, grease, or rust. When these contaminants are not properly eliminated prior to welding, they can evaporate and end up being caught in the weld, triggering problems. Using dirty or wet filler materials can present contaminations right into the weld, adding to porosity concerns. To mitigate these typical reasons for porosity, extensive cleansing of base steels, appropriate shielding gas option, and adherence to optimum welding specifications are vital methods in attaining high-grade, porosity-free welds.

Impact of Porosity on Weld Top Quality

The existence of porosity in welding can substantially endanger the structural stability and mechanical buildings of bonded joints. Porosity creates gaps within the weld steel, compromising its total toughness and load-bearing capacity.

Welds with high porosity degrees often tend to display lower impact strength and lowered capacity to deform plastically before fracturing. Porosity can restrain the weld's capacity to successfully transfer forces, leading to early weld failing and prospective safety hazards in essential frameworks.

Finest Practices for Porosity Avoidance

To enhance the structural honesty and high quality of bonded joints, what certain measures can be applied to reduce the event of porosity throughout the welding process? Utilizing the appropriate welding strategy for the Recommended Site certain product being welded, such as readjusting the welding angle and gun position, can additionally stop porosity. Normal inspection of welds and prompt removal of any kind of concerns determined throughout the welding procedure are vital practices to avoid porosity and generate premium welds.

Relevance of Proper Welding Strategies

Carrying out proper welding techniques is vital in making sure the structural integrity and quality of welded joints, building on the structure of reliable porosity avoidance actions. Welding techniques straight impact the general stamina and toughness of the welded next page framework. One vital element of appropriate welding techniques is maintaining the appropriate warm input. Excessive warmth can cause increased porosity as a result of the entrapment of gases in the Home Page weld swimming pool. On the other hand, insufficient warm might lead to insufficient blend, developing possible powerlessness in the joint. Additionally, making use of the suitable welding criteria, such as voltage, present, and take a trip speed, is crucial for accomplishing audio welds with very little porosity.

In addition, the option of welding process, whether it be MIG, TIG, or stick welding, need to straighten with the certain needs of the job to make sure optimal outcomes. Appropriate cleaning and preparation of the base metal, in addition to choosing the best filler product, are likewise vital elements of skillful welding strategies. By sticking to these finest techniques, welders can minimize the danger of porosity formation and generate top notch, structurally audio welds.

Evaluating and High Quality Control Procedures

Checking treatments are necessary to discover and avoid porosity in welding, guaranteeing the stamina and sturdiness of the final item. Non-destructive screening techniques such as ultrasonic testing, radiographic testing, and visual inspection are generally used to recognize prospective problems like porosity.

Carrying out pre-weld and post-weld assessments is also vital in preserving top quality control standards. Pre-weld inspections involve verifying the materials, devices settings, and sanitation of the workspace to stop contamination. Post-weld examinations, on the other hand, analyze the last weld for any kind of issues, consisting of porosity, and confirm that it fulfills specified requirements. Implementing a thorough quality control strategy that includes complete testing treatments and inspections is critical to reducing porosity problems and making certain the overall high quality of welded joints.

Final Thought

To conclude, porosity in welding can be an usual concern that impacts the high quality of welds. By recognizing the usual sources of porosity and executing finest methods for avoidance, such as appropriate welding strategies and screening measures, welders can make certain premium quality and reliable welds. It is vital to prioritize prevention techniques to minimize the incident of porosity and maintain the stability of bonded structures.

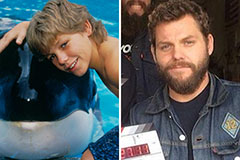

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!